This type of equipment is independent of the main filter and the pump system and is powered by a separate electricity source, usually in the form of a transformer that must be kept at least 3.0 m from the pool water, many times on the pool deck.

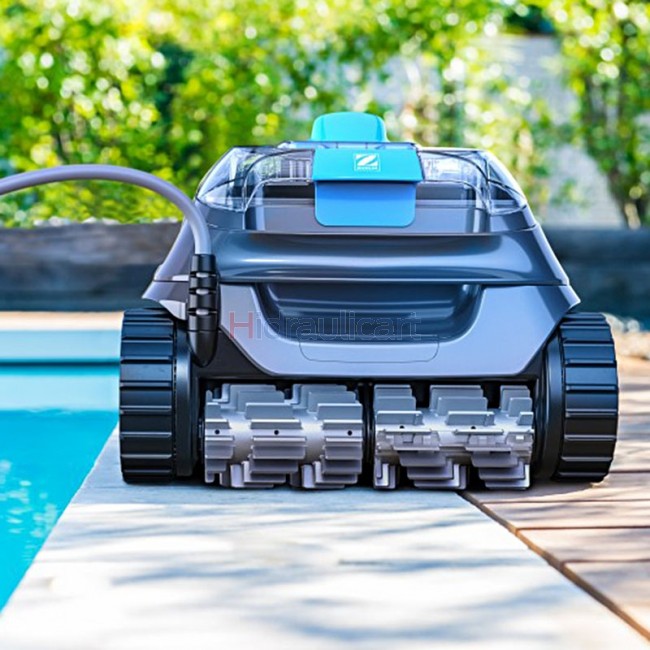

Robotic Pool Cleaners come equipped with two internal motors: one to suck water through an independent filter and return the filtered water at high speed back to the pool water. The second is a drive motor that is connected to rubber belts like a tractor or to rubber or plastic brushes by means of a shaft. The brushes, similar to paint rollers, are located on the front and rear of the machine and help to remove contaminating particles from the pool floor, walls and in some cases even the steps of the pool, depending on the size and configuration. They also direct the particles into the inner filter bag.

Robotic Pool Cleaner Zodiac CNX 30 iQ

RV 5500 Zodiac Pool Cleaner

An internal microchip is pre-programmed to switch on and off and reverse the direction of the drive motors. The chip will cause the robot to change direction when it hits a wall or the surface of the water after climbing the walls of the pool.

These vacuums can also be directed by sensors located on the impact bars which, in contact with objects such as a wall, cause an inverse in the direction, with a small displacement allowing it to move the width of a vacuole over each intersection of the pool . The delay timer is an important feature for many pools, as many turn off several circulation pumps during the night to allow suspended particles to settle to the bottom of the pool; after a few hours, the pool robot begins its cleaning cycle. This cleaning cycle is configured to be completed before the pumps are switched on again. While not necessary for proper pool cleaning, this feature saves energy and improves cleaning efficiency.

To move forward, backward, climb walls and steps, the automatic electric vacuum cleaners are based on three natural principles, traction and movement caused by the drive motor and brushes, buoyancy created by the large areas inside the machine that are filled with air and the force resulting from the high pressure of water being emitted from the top of the machine that pushes it against the floor and walls. Some electric robots use brushes made of polyvinyl alcohol (PVA), polyvinyl alcohol, which has a grip quality that allows the unit to almost stick to walls, steps and floors. They are also resistant to rubbish and oil, improving the service life of rubber or other synthetic materials.

The combination of these three natural principles, together with an internal mercury switch that informs the microchip that the unit has moved from horizontal to vertical while climbing a wall, allows it to change from upward to downward wall intervals at intervals pre-programmed in the average height of the walls of a swimming pool. Some robots have delayed timers that cause the robot to remain in the water line, where more garbage accumulates, resulting in a rubbing action, much like the wheels of a powerful car turning or peeling.

The main benefits of this equipment are the efficiency in terms of time, energy and cleaning capacity, as well as low costs and maintenance requirements. The main disadvantage is the purchase cost, which can vary from € 750 for floor cleaning machines to more than € 2,000 for more sophisticated residential units.