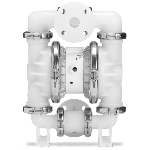

Product Description

Description

SEKO's Duotek pumps are known for their flexibility in pumping difficult liquids at low pressure and flow rate.

SEKO Duotek pumps are available in various sizes and different construction materials. Almost any type of liquid from highly corrosive acids, high viscosity paints, adhesives, food products and beverages can be pumped. The range of applications is practically unlimited.

Characteristics

• Variable flow and pressure, easy adjustment, without sophisticated controls;

• Portable and compact for use in various locations, optionally with transport cart application;

• Handles liquids with solid particles: ideal for abrasive and viscous products;

• Special air system: no lubrication, non-slip, no freezing;

• With a range of sizes and materials suitable for a wide variety of conditions and chemical fluids;

• Efficient performance: high flow rates and robust construction;

• Self-priming up to 6 meters: works in negative suction applications;

• Efficient air distribution design: low air consumption;

• Can be customized for specific applications: several output options available;

• Safe “dead head” function, against closing the outlet without damaging the pump.

Technical Characteristics

Suction diameter: 1/2” BSP and Flanged

Compression diameter: 1/2” BSP and Flanged

Air connection: 3/8” BSP

Maximum flow: 70 l/min

Maximum air pressure: 8 bar

Maximum lifting height: 80 m

Self-priming: 6 m

Maximum suction height: 9.8 m

Max solids passage: 3.5 mm

Noise level: 72 dB

Max viscosity: 25000 cps

Pump body: Polypropylene

Diaphragms: Santoprene

Ball valves: Teflon

Ball seat: Polypropylene

Orings: Teflon

Consult us to check whether the fluid you intend to pump is compatible with the materials of this pneumatic pump.

Documents

For more information, see the Catalog

For more information, see the Chemical Resistance Table of Pump Materials