Product Description

E-Tech is Franklin Electric's brand of high-quality stainless steel pumps. Its production takes place at Franklin Electric Srl, a company recognized for its high specialization in components for the pumping industry around the world.

Description

Centrifugal electric pumps were specially designed for increasing pressure in domestic and industrial water installations. All of its components in contact with water are made of stainless steel and are designed for applications in pressure equipment, refrigeration and heating systems. The pumps are available in AISI 304 and 316 versions, and stand out for their oversized coupling flange that allows easy and quick fitting with any standard motor, supporting all the axial load produced by the pump.

applications

Boiler supply, recirculation of hot and cold water for heating, refrigeration and air conditioning, pumping of clean water in civil, industrial and agricultural applications, irrigation and sprinkling, water distribution and pressure groups, washing and cleaning systems, water tunnels vehicle washing, water treatment plants, reverse osmosis systems.

Characteristics

All components in contact with liquid in stainless steel for versions I and N.

Carbon diffuser bearing to guarantee durability in dry operation (EV 30- 45-65-95)

Easy disassembly without special tools

Easy installation, in-line impulsion and suction output

Hydraulics completely made of stainless steel to guarantee durability and high performance

New hydraulic design to maximize efficiency

Oversized motor support and upper bearing that protects the motor bearing and minimizes axial force on the pump

For models with powers greater than 4 kW (motor>30 kg), the mechanical lock can be replaced without removing the motor

Tungsten carbide shaft and ring bearings

Standard mechanical closure (EN 12756 exDIN 24960) WRAS certified, balanced to EV 30-45-65-95

WRAS certified floating ring, in PPS for EV 1-3-6-10 and in PTFE for EV 15-20-30-45-65-95

Standard high-efficiency IE3 motor with motor-pump coupling B14 up to 4 kW and B5 from 5.5 kW

Tungsten carbide intermediate bearings to stabilize the rotor and prevent vibrations

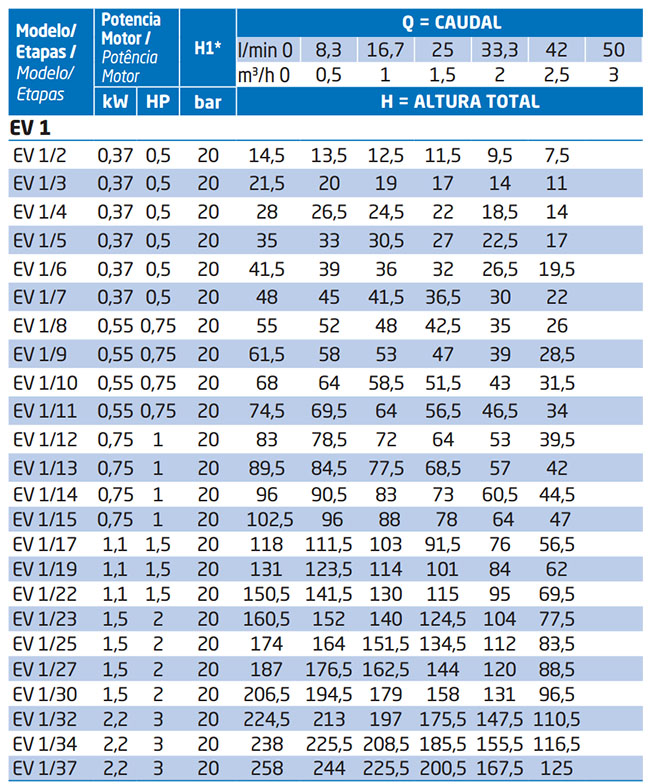

Specifications

Clockwise rotation, observing the pump from the top

In-line impulsion and suction output

Working curves in accordance with ISO 9906, type 3

Liquid working temperature between -15 ºC and 120 ºC

Materials suitable for drinking water, WRAS, ACS, KTW certificate

Maximum working pressure: oval flange 16 bar, round flange and Victaulic and Clamp couplings 25 bar

Motores eficiência energética IE3 - MEI >= 0,7

Specification

Documents

For more information, see the Catalog

For more information, see the Installation Manual