| Product Name | Price | Delivery | Expedição | Qty |

|---|---|---|---|---|

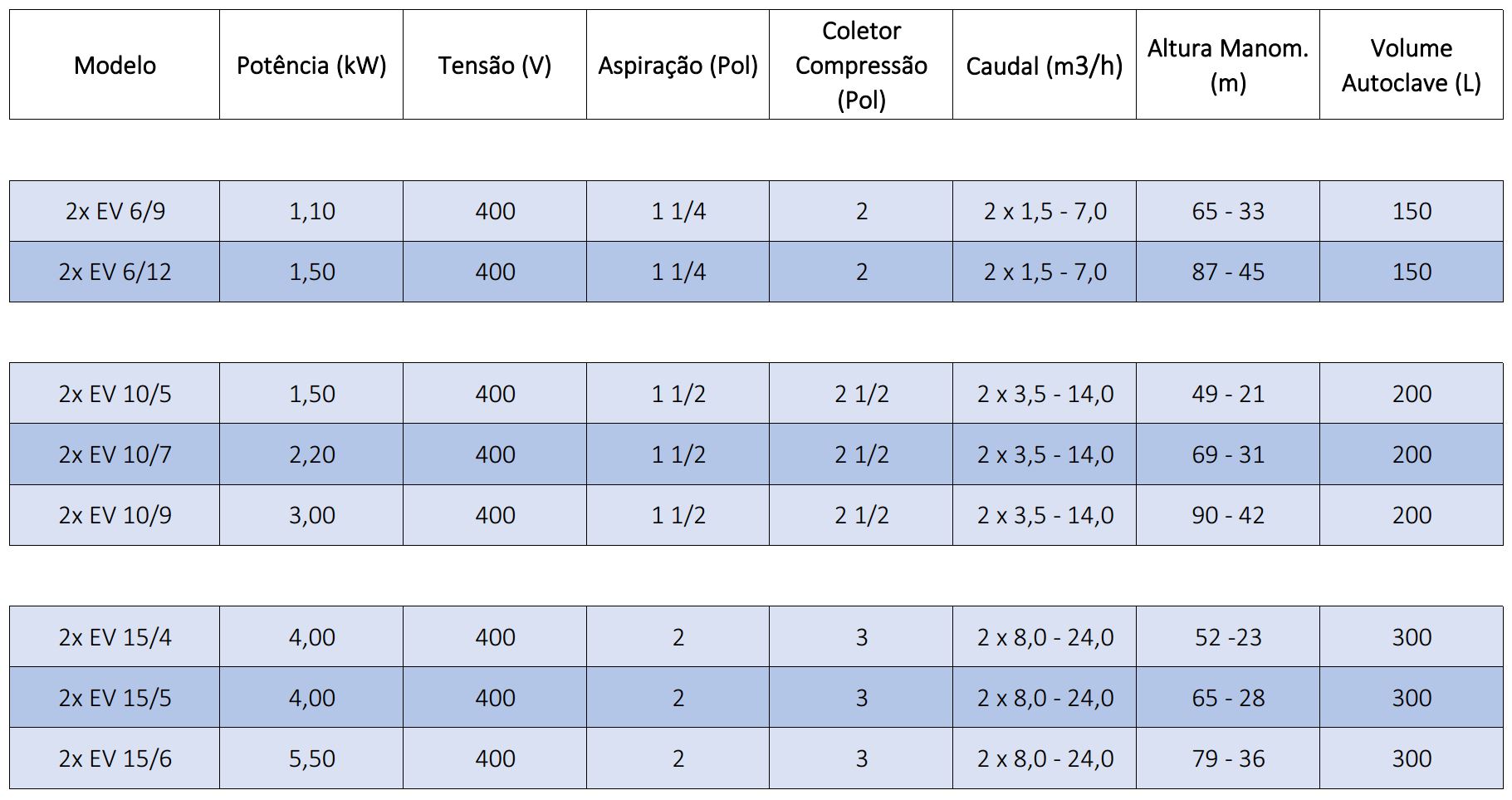

| Etech-Franklin Dual Central 2x EV 6/9 Cód.ETECDEV-06.09A150 |

€3,966.00

|

5 dias úteis | ||

| Etech-Franklin Dual Central 2x EV 6/12 Cód.ETECDEV-06.12A150 |

€4,553.00

|

5 dias úteis | ||

| Etech-Franklin Dual Central 2x EV 10/5 Cód.ETECDEV-10.05A200 |

€4,864.00

|

5 dias úteis | ||

| Etech-Franklin Dual Central 2x EV 10/7 Cód.ETECDEV-10.07A200 |

€5,142.00

|

5 dias úteis | ||

| Etech-Franklin Dual Central 2x EV 15/4 Cód.ETECDEV-15.04A300 |

€6,141.00

|

5 dias úteis | ||

| Etech-Franklin Dual Central 2x EV 10/9 Cód.ETECDEV-10.09A200 |

€6,517.00

|

5 dias úteis | ||

| Etech-Franklin Dual Central 2x EV 15/5 Cód.ETECDEV-15.05A300 |

€6,813.00

|

5 dias úteis | ||

| Etech-Franklin Dual Central 2x EV 15/6 Cód.ETECDEV-15.06A300 |

€7,835.00

|

5 dias úteis |

Product Description

Pressurization system consisting of two pumps coupled in parallel and mounted on a common base with all the necessary accessories and electrical panel. The pressurization center, of the Etech-Franklin type, equipped with the following main components:

- Main electric pump;

- Secondary electric pump;

- Hydropneumatic autoclave;

- ELETRIC board;

- Interconnection Accessories and Components.

Eletrobomba principal e secundária

Two multistage centrifugal electric pumps, with impellers, shaft, intermediate chambers and upper and lower bodies in AISI 304 stainless steel, adjustable mechanical seal and bearings self-lubricated by pumped water. The pump body is fixed between the base and the motor support by means of tie rods. The motor efficiency level is IE3 level.

Depósito hidropneumático

In painted sheet metal from Global Water or EDS. Replaceable membrane tank and polypropylene coating inside the flange that ensures maximum watertightness and avoids corrosion problems;

Quadro Eléctrico

Built in a polyester box including: four-pole general cut switch, set of circuit breakers, MAN-O-AUT switches, three-pole contactors with thermals, toggle relay, high level alarm, operating signals and thermal tripping;

The hydropneumatic control unit performs the start and stop system using pressure switches. As soon as there is water consumption, the first supply is made from the reservoir. When the pressure drops to the starting regulation level, one of the pumps starts working. If water consumption continues to increase, the 2nd pump starts working. The pumps stop automatically as soon as they reach the respective stop pressure, for which it was set. A toggle relay in the electrical panel changes the starting sequence of the pumps in each operating cycle, thus allowing uniform use of the pumps.

Acessórios de interligação e Componentes

Two Telemecanique Pressure Switches;

A manometer in a glycerine bath;

One AISI304 stainless steel compression and aspiration collector;

One check valve on each pump;

One Compression Disconnect Valve for each pump;

A General shut-off valve on compression;

A settlement base;

A connecting sleeve between the collector and the hydropneumatic tank;

A 5m long level switch for installation in tanks.